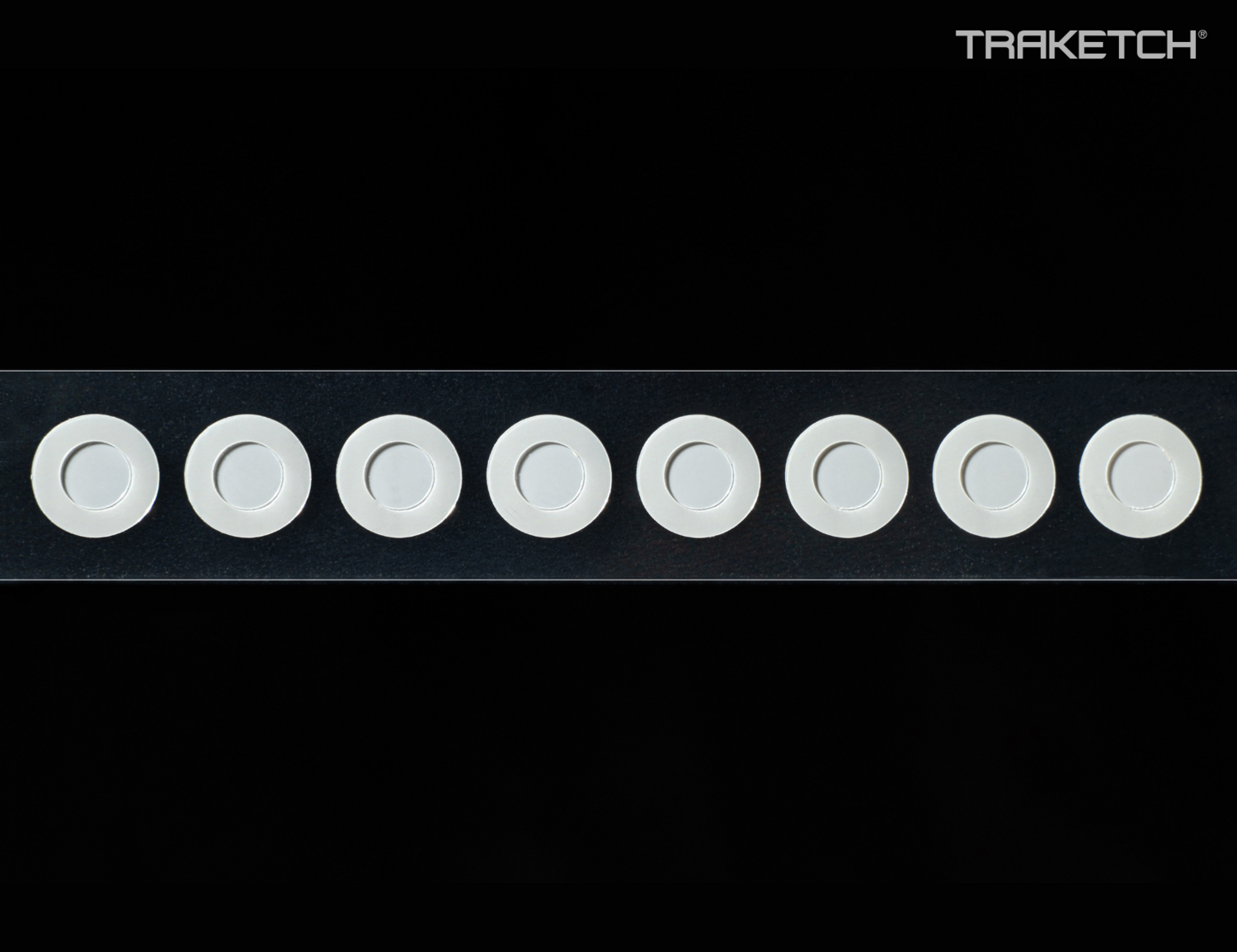

Self-adhesive Membrane Pads (adhesiveVENTpads)

Our "Firewall" to protect your products

Your contact person

Kevin Eckert

Head of FLUXX

Packaging & Industrial

Our adhesiveVENTpads are Membrane Discs equipped with an adhesive ring in various sizes with hydrophobic and oleophobic properties. They are supplied on rolls and are all PFOA/PFCA-free & PFAS-free upon request, of course.

Below you will find the most common membrane variants, further information on specifications and conformity, your product benefits and a selection of application examples. Read more >

Specifications & conformities

| Chemical restistance: | Go to > |

|---|---|

| Temperature resistance: | PET with modified adhesive up to 110 °C PET, PET-non-woven-supported with modified adhesive up to 110 °C These information refer to the respective materials. The functions must be approved for each application itself. |

| Sealing compatibility: | Go to > |

| IP-protection class suitability: | Yes |

All product data given on this website represent typical values.

Benefits

- Available in several standard sizes

- Safe pressure compensation, steady airflow and continuous venting

- Reliable protection against environmental influences such as foreign particles, water, and other liquids.

- Easy product integration (also in existing components)

- Self-adhesive membrane pads can be installed either inside or outside the component and have minimal space requirements

- Can be applied manually, semi-automatically, or fully automatically

- Excellent adhesion on smooth surfaces – especially to plastic, aluminum, and steel

- Individually customizable (e.g. formats and adhesive types)

- Narrow tolerances of the membrane parameters

- Water and oil repellent surface (hydrophobic/oleophobic)

- Suitable for IP protection classes

- PFOA/PFCA-free & PFAS-free upon request (confirmed by accredited test laboratories)

- Production under clean room conditions in accordance with ISO class 8

- Certified according to DIN EN ISO 9001 & 13485

Product found? Order now >

Your product not yet included? Customization options >

Your contact person

Kevin Eckert

Head of FLUXX

Packaging & Industrial

adhesiveVENTpads Standard product portfolio

Our hydrophobic and oleophobic membrane adhesive pads (adhesiveVENTpads) are available in a variety of standard sizes, and upon request, customized for you in different measurements, pore sizes, and additionally with fleece reinforcement.

Show products: Self-adhesive Membrane Pads

adhesiveVENTpad

Ø 5.0 / 2.0 mm

0.4 µm PET

Item Number: 090065

Material: unsupported Polyester (PET)

Membrane with modified adhesive

Pore size: 0.4 µm

Backing: None

Membrane thickness: 36 µm

Filter area: 0.03 cm2

Air flow rate: 7.0 L /(min cm2 bar)

WEP: 1.8 bar

Surface: hydrophobic & oleophobic

Minimum order quantity: 1,000 Pads

Quantity per roll: 7,000 Pads

adhesiveVENTpad

Ø 7.0 / 3.0 mm

0.4 µm PET

Item Number: 090067

Material: unsupported Polyester (PET)

Membrane with modified adhesive

Pore size: 0.4 µm

Backing: None

Membrane thickness: 36 µm

Filter area: 0.07 cm2

Air flow rate: 7.0 L /(min cm2 bar)

WEP: 1.8 bar

Surface: hydrophobic & oleophobic

Minimum order quantity: 1,000 Pads

Quantity per roll: 5,000 Pads

adhesiveVENTpad

Ø 7.5 / 3.0 mm

1.0 µm PET

Item Number: 090056

Material: unsupported Polyester (PET)

Membrane with modified adhesive

Pore size: 1.0 µm

Backing: None

Membrane thickness: 35 µm

Filter area: 0.07 cm2

Air flow rate: 20 L /(min cm2 bar)

WEP: 0.6 bar

Surface: hydrophobic & oleophobic

Minimum order quantity: 1,000 Pads

Quantity per roll: 5,000 Pads

adhesiveVENTpad

Ø 8.0 / 4.0 mm

0.4 µm PET

Item Number: 090071

Material: unsupported Polyester (PET)

Membrane with modified adhesive

Pore size: 0.4 µm

Backing: None

Membrane thickness: 36 µm

Filter area: 0.13 cm2

Air flow rate: 7.0 L /(min cm2 bar)

WEP: 1.8 bar

Surface: hydrophobic & oleophobic

Minimum order quantity: 1,000 Pads

Quantity per roll: 5,000 Pads

adhesiveVENTpad

Ø 8.0 / 4.0 mm

1.0 µm PET

Item Number: 090020

Material: unsupported Polyester (PET)

Membrane with modified adhesive

Pore size: 1.0 µm

Backing: None

Membrane thickness: 35 µm

Filter area: 0.13 cm2

Air flow rate: 20 L /(min cm2 bar)

WEP: 0.6 bar

Surface: hydrophobic & oleophobic

Minimum order quantity: 1,000 Pads

Quantity per roll: 5,000 Pads

adhesiveVENTpad

Ø 10.0 / 5.5 mm

0.4 µm PET

Item Number: 090068

Material: unsupported Polyester (PET)

Membrane with modified adhesive

Pore size: 0.4 µm

Backing: None

Membrane thickness: 36 µm

Filter area: 0.24 cm2

Air flow rate: 7.0 L /(min cm2 bar)

WEP: 1.8 bar

Surface: hydrophobic & oleophobic

Minimum order quantity: 1,000 Pads

Quantity per roll: 4,000 Pads

adhesiveVENTpad

Ø 12.7 / 7.1 mm

0.4 µm PET

Item Number: 090072

Material: unsupported Polyester (PET)

Membrane with modified adhesive

Pore size: 0.4 µm

Backing: None

Membrane thickness: 36 µm

Filter area: 0.40 cm2

Air flow rate: 7.0 L /(min cm2 bar)

WEP: 1.8 bar

Surface: hydrophobic & oleophobic

Minimum order quantity: 1,000 Pads

Quantity per roll: 3,000 Pads

adhesiveVENTpad

Ø 12.7 / 7.1 mm

1.0 µm PET/PET

Item Number: 090064

Material: Supported Polyester (PET)

Membrane with modified adhesive

Pore size: 1.0 µm

Backing: PET-non-woven

Membrane thickness: 140 µm

Filter area: 0.40 cm2

Air flow rate: 26 L /(min cm2 bar)

WEP: 0.6 bar

Surface: hydrophobic & oleophobic

Minimum order quantity: 1,000 Pads

Quantity per roll: 3,000 Pads

adhesiveVENTpad

Ø 14.0 / 8.0 mm

0.4 µm PET

Item Number: 090069

Material: unsupported Polyester (PET)

Membrane with modified adhesive

Pore size: 0.4 µm

Backing: None

Membrane thickness: 36 µm

Filter area: 0.50 cm2

Air flow rate: 7.0 L /(min cm2 bar)

WEP: 1.8 bar

Surface: hydrophobic & oleophobic

Minimum order quantity: 1,000 Pads

Quantity per roll: 3,000 Pads

All product data given on this website represent typical values.

Product found? Order now >

Your product not yet included? Customization options >

Your contact person

Kevin Eckert

Head of FLUXX

Packaging & Industrial

Application examples

From electronic components in automobiles to housing components for medical technology: TRAKETCH® adhesiveVENTpads from SABEU are self-adhesive membranes that protect sensitive parts and enhance their durability. Our membrane adhesive pads ensure ventilation of components, equalize pressure differences in housings, and prevent the intrusion of unwanted particles, moisture, water, and other liquids. Explore our adhesiveVENTpads here for a variety of different applications.

Life Sciences & Medical

Hydrophobic & oleophobic

| Application | Pore size |

|---|---|

| Sterile Venting of | |

| Suction containers: | 0.2 µm |

| Diagnostic devices: | 0.2 µm |

| Insulin pumps: | 0.2 – 1.0 µm |

| Hospital beds: | 0.2 – 1.0 µm |

| Neurostimulators: | 0.2 – 1.0 µm |

| Sterilization boxes: | 0.2 µm |

| Ostomy bags: | 0.2 µm |

| Transducer protectors: | 0.2 µm |

| Drip chambers: | 0.2 µm |

| Urin bags: | 0.2 µm |

| Cell culture containers: | 0.2 µm |

Hydrophilic

| Application | Pore size |

|---|---|

| Cancer cells (RCC): | 5.0 - 8.0 µm |

| Artificial organs: | 0.08 µm |

| Legionella test: | 0.2 – 0.4 µm |

| Pap test: | 5.0 – 8.0 µm |

| Particle analysis: | 0.2 – 0.8 µm |

| Sterile laboratory filtration: | 0.2 µm |

| Cell and gene therapy: | 0.4 µm |

| Cell culture: Application advisor for Cell Culture Inserts / Plates: | 0.2 – 8.0 µm cellQART® Online Advisor > |

Industrial

Hydrophobic & oleophobic

- Mobile electronics

- Automotive & outdoor electronics

- Lighting technology

- Sensors & measurement technology

- Battery technology & eMobility

- Control technology

- Acoustics & optoelectronics

- Electronic medical technology

Hydrophilic

- Filtration technology

- Environmental analysis

- Measurement analytics

- Air humidification

Packaging

Hydrophobic & oleophobic

- Liquid foods

- Hazardous substances and other chemicals

- Agrochemicals

- Cleaners

- Hygiene and care products

For more information on application possibilities, please click here:

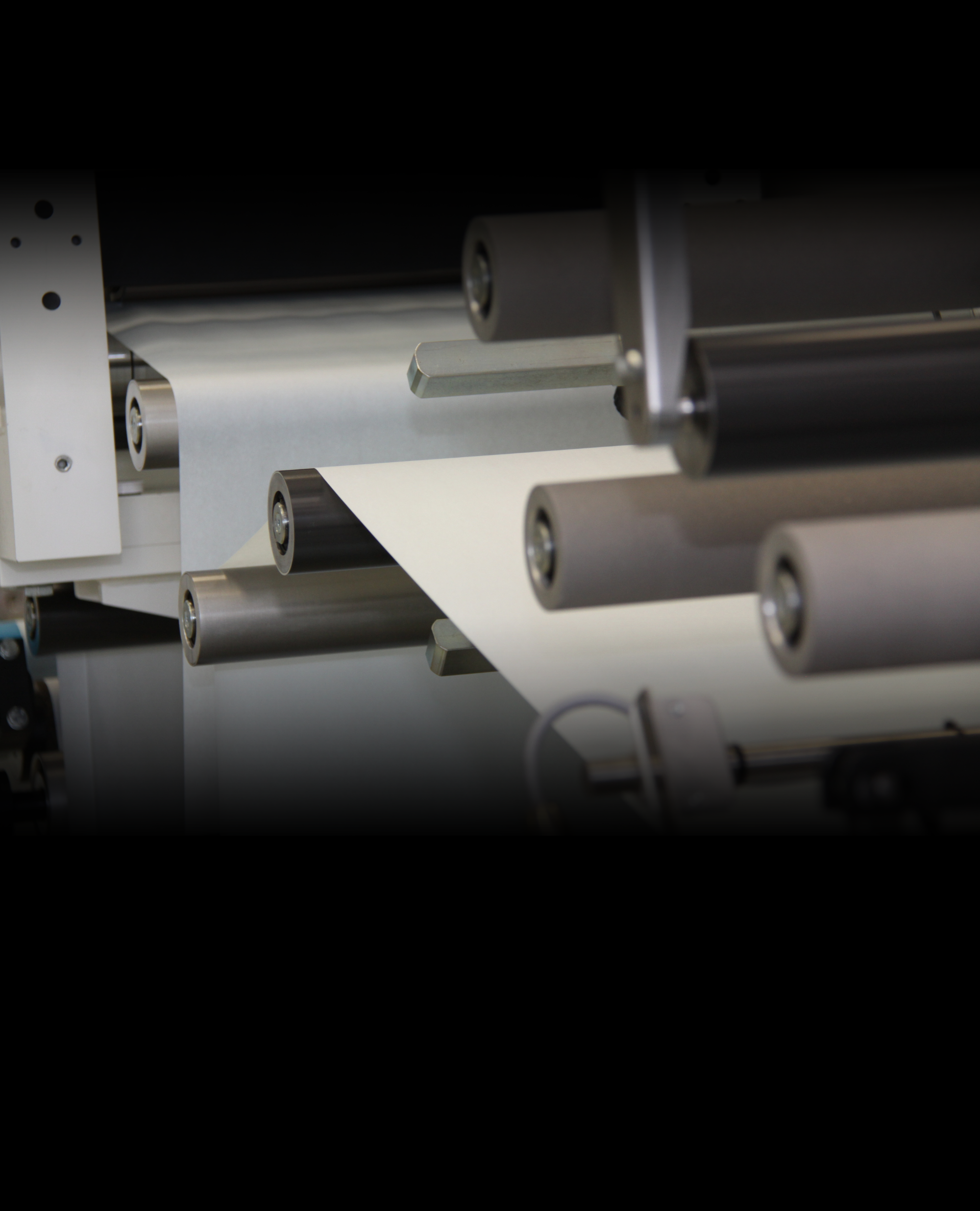

Convenient Installation

SABEU membrane adhesive pads are available in a variety of standard sizes. With our specially developed TRAKETCH® technology, we can customize the membrane adhesive pads to meet customer-specific requirements.

The product advantage: Our self-adhesive membrane pads are made of hydrophobic and oleophobic membranes that ensure airflow while reliably safeguarding from moisture and dirt.

The TRAKETCH® adhesiveVENTpads are practical to use and can be easily applied to components/parts. Thanks to specially modified adhesives, our membrane adhesive pads adhere to a wide range of materials, such as various plastics, aluminum, and steel. The adhesive pads can be applied manually, semi-automatically, or fully automatic. Just peel, stick, and solve!

Product found? Order now >

Your product not yet included? Customization options >

Your contact person

Kevin Eckert

Head of FLUXX

Packaging & Industrial

Customer voice

Let’s collaborate on your next project! Listen here to what our customer Porsche eBike Performance GmbH (FAZUA GmbH) says about SABEU and our adhesiveVENT pads in this video:

Product found? Order now >

Your product not yet included? Customization options >

Your contact person

Kevin Eckert

Head of FLUXX

Packaging & Industrial

Additional membrane configurations

Discover our selection of other standard formats and further product solutions below. You will find an overview of our membrane product variants and your customization options on the overview page of our membrane product portfolio >.

Membrane

Discs

Discs with defined diameters are already designed for immediate processing and assembly.

Membrane

Sheets

Sheets as test samples are ideal for semi-automated and manual production steps.

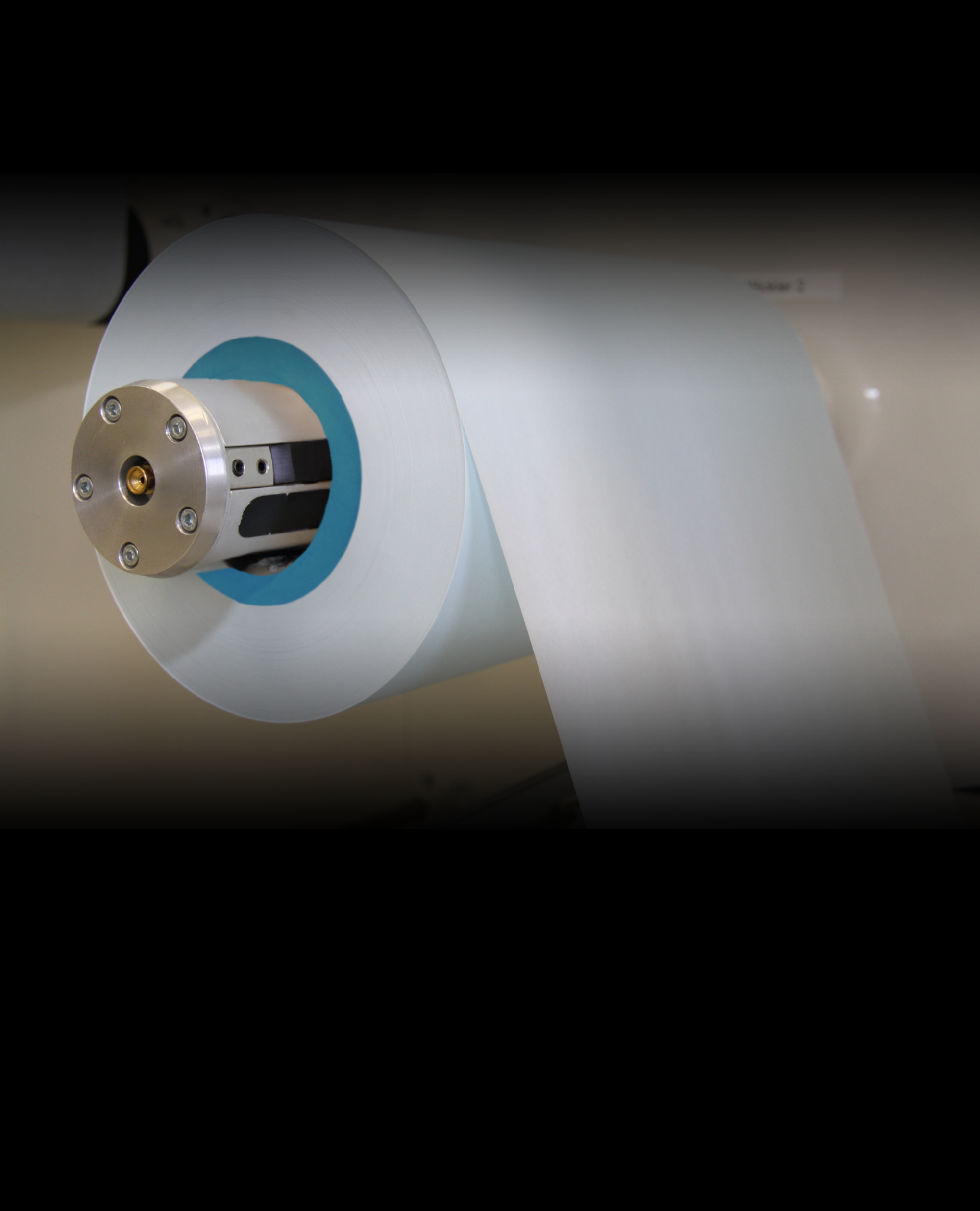

Membrane

Rolls

Rolls include the opportunity to process our membranes directly in your production process.

All our other membrane product solutions for cell culture and packaging are combined in our own brands separately – click here to continue:

Customized product solutions

Do you require membrane products beyond our standard product portfolio? As the manufacturer of filter membranes and plastic components, we can develop a solution specifically for your requirements.

Certifications and conformities

Contact person and product orders

Your contact person

Kevin Eckert

Head of FLUXX

Packaging & Industrial

Your contact person

Jennifer Hughes

Sales Lead Americas